One of the things that keeps life interesting is trying new things: a new adventure; the beginning of something different. Sometimes that new beginning is abrupt. You decide there needs to be a change of scenery, and you cast off and head toward a new horizon. Other times, you just drift into it as circumstances evolve, and before you know it you’re neck deep in something that wasn’t really on your to-do list.

It was like that with the webstore we’ve just launched on this site. I hadn’t imagined, even when rockclimbing full time in Yosemite in the 90s, that I would one day start a climbing gear company. And we would never have done it at all if not for the long and winding road that took us to sea on a home-made boat, washed us up in Rhode Island, and by the merest accident landed me a job in a rigging shop.

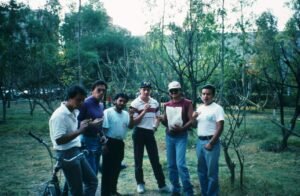

Now, all my life I’ve relied heavily on home-made things. It was just what was done, when store-bought couldn’t be afforded, and most of us climbing at the local crag in Mexico City simply couldn’t. So you only bought what you couldn’t make, and did without what you could neither make nor buy. Everyone had, or at least started with, hand-made harnesses. There was a Mexican climbing-shoe micro-industry (I made a pair); there were homemade camming devices (I have a set); backpacks, slings, belay devices, bolt hangers—you name it, someone had improvised it as an expedient of necessity. I guess it was that which gave me the mindset to look past the shiny of a mass-produced bit of gear to its substance to see how it was made. It also allowed me to improvise and build so much of Ganymede, the 31-foot sailboat that brought us to New England from California.

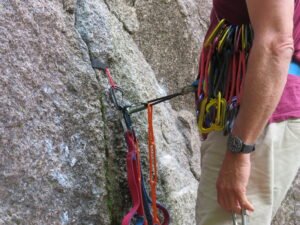

And it was that mindset, years later, that started turning mental wheels while I spliced rope and made covered Dyneema loops in the loft at RigPro in Rhode Island. Could not some of this this lighter, stronger stuff developed for racing boats be adapted to climbing? Compared to the sailboat-racing industry, which is far bigger, older, and has gobs of money to devote to innovation, the world of climbing gear development is relatively small and new. I’d noticed also, ever since I first put to sea, that there wasn’t a wide bridge between the industries. Things that climbers had been doing for decades, like comfortable sit harnesses, were just being “discovered” by sailors, and skinny rope technology in everyday use for sailors was not even conceivable to climbers.

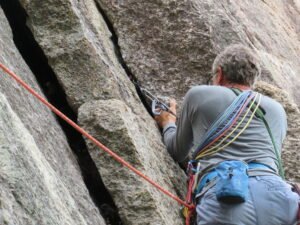

Everything new is commonly treated with suspicion: when bar-tacked slings first came out, people didn’t trust the stitching, and I know some who cut the slings off their new cams to tie on a knotted sling. When sewn Spectra runners first appeared in the mid-90s, we were leery: how could something so thin be as strong as the 1” tubular nylon webbing of our forefathers? Even so now, as I show people the super-slim spliced slings devoid of sewn seams that I’ve developed, there’s a measure of disbelief. But I’m getting ahead of myself.

I had learned, during an earlier attempt at making boat rigging products, that product development, prototyping, testing, production, and finally sales are not low-budget activities. Just try filing for a patent sometime! This time I thought a partnership was in order. I believed—I still do—that the Seamless slings and quickdraws I was working on should be interesting to the established gear companies. So I sent out an elevator pitch, and even samples, to every gear maker I could think of: Black Diamond, DMM, Wild Country, Edelrid, Metolius—I even got an introduction to Sterling Ropes and drove to Maine to give them a four-hour in-person presentation. The sound of the occasional offhand rejection was nearly drowned by the overwhelming uproar of crickets. I might as well have dropped my samples down a well.

In the meantime, climbing boat masts as a rigger and climbing rocks in New Hampshire with the Seamless runners convinced me that the day of sewn goods is truly over. Spliced gear is where it’s at, and I just need to convince the rest of the world, without the help of other companies, if necessary.

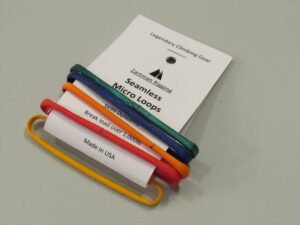

One hurdle for most people I showed the gear to was the absence of a rating tag: most commercially available gear is rated by a certification agency, such as Underwriter’s Laboratories or ASTM are. The oldest such agency for climbing gear is the International Alpinist’s Union, or UIAA. It was not greatly difficult to register with them, send samples off for testing, and in due course get permission to put their name and logo on two sorts of Seamless runners.

That was the last hurdle for IME, an independent climbing shop in North Conway, NH, who promptly put the tagged runners on their shelf, and gave me the confidence to start the next round of certifications. And so, without having really set out to, we started a climbing gear company—Zartman Rigging, the world’s first maker of Seamless, UIAA-labelled, covered Dyneema runners, quickdraws, and other climbing gear. What you see in the webstore is just the tip of the iceberg: there’s half a dozen other notions in progress, and seeds of others beyond them, just waiting for a chance. Whatever happens, this is a new beginning for us, and it’s surely been interesting so far.