It was all the way back in the spring that I last blogged about Antigone’s boat build. An incredibly busy summer of boat captaining and rigging has come and gone, leaving us slightly breathless, but with some progress to report on the build. We last left off as we were putting longitudinal stingers, kind of like purlins, along the hull, at decent intervals to support the core foam we wanted to fiberglass over.

Looking back, it might have been worthwhile buying nicer wood than simply furring strips to use, which had knots and checks and other blemishes, but then, that might have cost a lot more. The furring strips weren’t quite flexible enough to make the tight turn of the full bows, so we planed them all down to a half-ich, then ripped them lengthwise to make narrower, flexi-er strips.

To our great satisfaction, it only took finishing nails, which are much cheaper and easier than screws, to hold the purlins onto the OSB frames, and with a couple hours at a time of work here and there over the early summer, we soon had the hull looking like a loose wicker basket.

H-80 Divinycell is the standard foam for fiberglass coring material, but it’s rather pricey, and only came in 1/2” thick sheets. A similar foam from Airex, with the 3/8” thickness we wanted, was eventually found by the case for a far better price. We’d thought about double-diagonal planking the hull with the core foam, kind of like an epoxy-over-ply build, but some testing determined that a single layer of diagonal foam planks over the purlins would be enough to hold the shape for glassing over.

With a cutting jig made from a scrap of plank, a razor blade, and a clamp, Antigone quickly cut a dozen-odd sheets into 4-inch planks. We tried at first to hot-glue them to the purlins, but it was the hottest part of the summer when we began, and the glue would just soften up and let go. It was necessary to use temporary screws, then run beads of hot glue behind them along the purlins before taking out the screws. In the end, we wound up buying several hundred screws so we could leave them in until just before glassing time.

Planking the hull with diagonal strips worked surprisingly well up until the planks needed to twist and bend in too many directions near the bows. We changed the direction of the strips until the boat resembled parquet, and still had to cut an arc into some of the pieces to make them fit. But that was minimal, especially compared to planking a hull the normal way, and gaps didn’t really matter too much, since the foam is just a shape to glass against.

Once the hull was all planked, we glued some naughty edges down with Bondo, did a lot less longboard fairing than we thought we would have to, and removing all the screws, laid two thin coats of chopped strand mat over the whole thing. It took several days, and a few different versions of a temporary scaffolding, to get that done, but it was immensely satisfying to have the entire hull finally protected and stabilized before having to set the project aside for a very different thing.

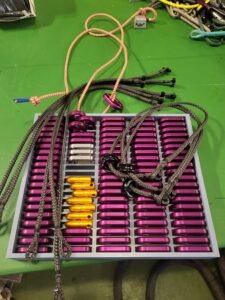

The alert reader will remember a climbing gear venture I mentioned a few posts back. Continuing to develop products without any real increase in sales had begun to hobble our ability to invest in more development. It was time to up the ante, and my idea of flying to Yosemite to show samples during peak climbing season for two weeks was trumped by Danielle’s idea of driving cross-country and visiting every climbing shop we could find along the way. Several salesmen have told me the best way to make sales is to drop by in person, and sales were what we needed. On Oct 1, we loaded up the minivan with six big boxes of gear, put a piece of plywood on top to sleep on, and headed for New Paltz, New York, for a first stop at the Gunks.

The plan was not only to visit shops and spread gear joy, but to offer a hands-on splicing workshop wherever we go, so folks can learn and understand basic splicing. Not every place we reached out to responded, and not every one that did could host a workshop, but after three weeks on the road, the trip has been far more successful than we had dared to hope. Nearly every shop we’ve visited, whether we contacted them in advance or simply walked in, has bought inventory outright, and the workshops have been very well received. We’re just about to head south for Atascadero, then begin the eastward push through Joshua Tree, Red Rocks, Moab, and Boulder, showing gear, teaching splicing, and making new friends as we go.

It’s a little odd, leaving the three children to self-tend for the first time ever, and for so long, but they seem to be thriving at home. And it’s a little odd, as well, living in a van after being used for so long to a house, and before that a boat, but everything can be got used to, and the reception the gear is getting is making the trouble worthwhile.

We’re in Yosemite just now—where I first lived on my own after high school in the freedom of responsibility; where Danielle and I first met; where the whole trajectory of our lives together began, and every tree and rock and river bend holds a memory. Parked by El Cap Meadow yesterday, catching up with old friends and contemplating life in the autumn sunshine, someone asked, “how’s it feel to be the next company that began by selling gear out of the back of a van?” He was talking of course about legends like the Fish, the Frog, John Yates, and Yvon Chouinard, who all began this way, with varying degrees of success. I pondered for a moment, with a couple twenties–the price of some Seamless loops–still folded in my hand. “Feels pretty good for now, I guess.” A golden leaf fluttered down and landed on the open tailgate, gleaming in the westering sunshine. “It’s not a bad way to start.”